PolyWorks’ biggest problem last year was finding enough people to triple the size of its workforce. Business has been very good for the North Smithfield designer of foams, plastics and gels, according to co-owner and Executive Vice President Roger LaFlamme. The best news is that it is only expected to get better.

“Ramping up a company quickly is challenging and so is finding the right people. When you are running three shifts you have to build a management team, you have to find all the different levels of workers and you have to train. And you have to do that when there is a lot of pressure from your customers because you can’t make enough, fast enough,” he said.

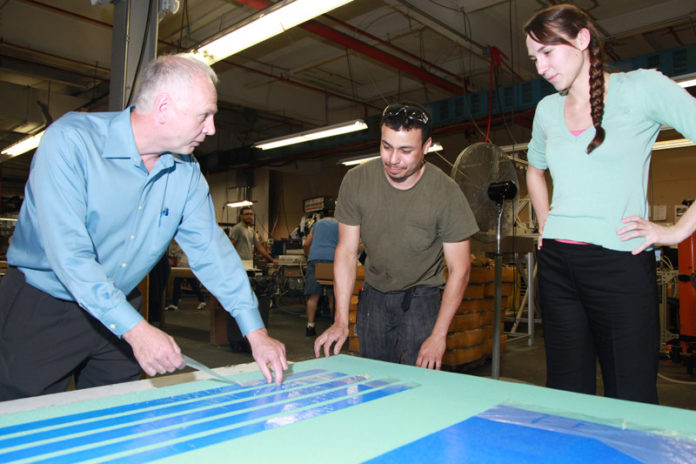

PolyWorks assists their clients in researching, designing and manufacturing products, such as gel coatings for pen grips, padding for athletic equipment, shoe inserts and bedding material. Their recent growth has been so expansive that in March, the company teamed with the R.I. Department of Labor and Training’s Business Workforce Center to recruit applicants for production-line and machine-operator positions.

“At one point I think we had the largest number of on-the-job trainees in Rhode Island,” LaFlamme said.

In an economy that’s been down for four years, PolyWorks’ story is welcome news, but initially growth was slow.

The company started in 2003 when its three original partners – LaFlamme, Daniel Wyner and Richard Fox – decided to form a startup dedicated to designing new technology.

PolyWorks has since excelled in meeting the needs of other companies and solving their problems. “Most of the growth in our company has been the result of developing proprietary molding technology for urethane foams. We started a licensing agreement with Rogers Corp. [in Woodstock, Conn.] and at the same time G-Form [Providence] started selling that technology and it exploded,” he said.

They developed a process for Rogers Corp. to mold their own sheets of foam into three dimensions. At G-Form, PolyWorks molds all of the company’s products. “That’s what really caused our growth over the last two years,” LaFlamme said. However, there is also no doubt that their products are desirable across the board, as products such as gel-sole inserts and pen and pencil grips become increasingly popular.

In order to research, design and manufacture their product, PolyWorks is a multidimensional firm. Industrial engineering is needed for product design and mechanical experience is needed to determine how the product can be made. Process engineering is needed to refine the end result. Everything they need, including the required tools and manufacturing devices, must be invented and fabricated on-site. They also manufacture, license and patent materials, designs and processes. With a master’s in business administration, LaFlamme’s role has evolved into the general manager of the company.

LaFlamme also said that because PolyWorks is a small, privately owned company, banks still don’t want to lend money unless they get personal guarantees, a problem they had faced in the past. “Thankfully, the good news is that we don’t need the bank right now.”

For the next two years the company’s outlook is bright based solely on the impact-protection market. LaFlamme anticipates growth in the furniture and bedding industry, as well as a greater focus on safety equipment and expects their total employees will rise. One of their current projects involves improving padding protection for helmets used in the National Hockey League, having subcontracted with a company that is ultimately responsible for designing an improved helmet.

But there are always pressures to reduce costs and the threat of overseas competition is always an issue.

“There’s always a threat of business going offshore when people are trying to remove costs,” LaFlamme said. “Thankfully most of our end-customers want to be “Made in the USA.” •

COMPANY PROFILE

PolyWorks Inc.

OWNER: Roger LaFlamme, co-owner and executive vice president

TYPE OF BUSINESS: Material design and manufacturing

LOCATION: 1 Tupperware Drive, North Smithfield

EMPLOYEES: 105

YEAR ESTABLISHED: 2003

ANNUAL SALES: WND